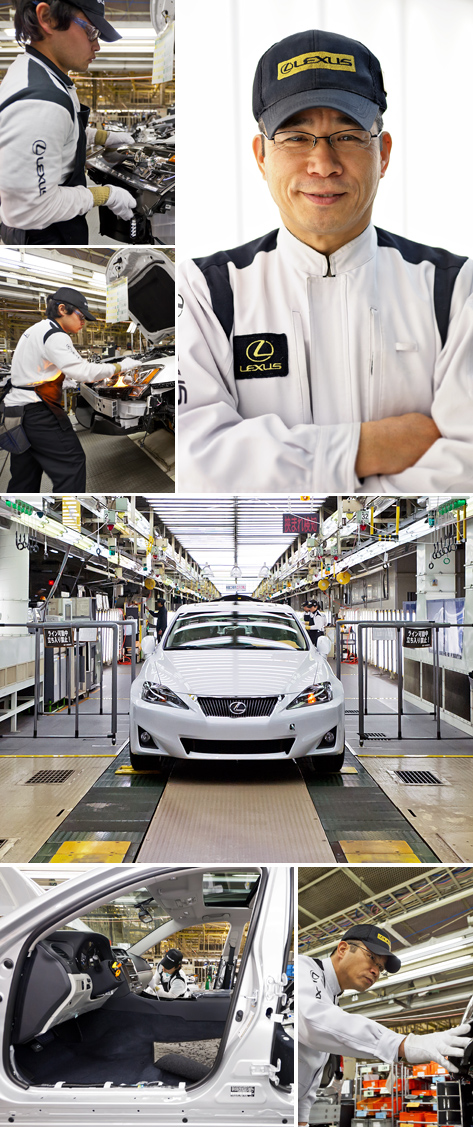

Tanaka spent some time working assembly-line shifts his entire career. Before moving on the process of preparing new models for production, he began his journey at Lexus in charge of the chassis. Within this role, Tanaka was in charge of deciding which parts will be assembled as to what order, to ensure the new model line would run as smoothly as you possibly can.

Tanaka now leads a crew that puts the finishing touches on the parts that have been completed by their colleagues at the press, painting and body stations, as the vehicle assembly takumi. They bolt on doors and wheels, attach headlights, insert the dashboard and connect electronic circuitry – all told there are actually 350 steps in this section. What they do requires artistry, speed, dedication and precision – enough of each to get the Lexus Skill Certification. They get only two minutes per car for each and every process. Nevertheless, all 2,800 parts must connect and align precisely – just as detailed on the original blueprints, and assembled to the strictest of standards. “”It is my responsibility to ensure that each worker maintains their skill set at the same level as when they first acquired their certification. To be certain of this, I check their work with my own, personal eyes each day, and give them personal advice and instruction,”” he says. This method of handing down knowledge from personal experience refines the process – ensuring Lexus vehicles are made with consistently high precision.